Upstream equipments

Mixers

- High speed mixer

- Our high-speed mixer is equipped with high efficiency 4-layer abrasion proof blades; we can also customize blades as per material characteristics.

- We have 3 types of high speed mixer, type A, B, and C, and each has different features. For type A, the mixer adopts fixed rev speed AC motor which is suitable for general material mixing; type B adopts pole change 2 step speed AC motor which is suitable for large volume material mixing; type C adopts stepless variable speed inverter AC motor where mixing speed can be adjusted against different materials.

- Feeding capacity: 15L to 1050L.

- Cooling mixer

- Vertical cooling mixer

- This type of cooling mixer is suitable for large quantity of output. This unit is equipped with baffles to increase cooling efficiency.

- Tank capacity: 70L to 2450L.

- Horizontal cooling mixer

- Horizontal cooling mixer adopts fixed rev speed AC motor suitable for general material mixing. Motor and reducer are installed vertically to save space. Both sides of mechanical seal utilize compressed air purge seal design.

- Tank capacity: 1000L to 5000L

- Vertical cooling mixer

- Horizontal cooling/heating mixer

- This type of mixer adopts fixed rev speed AC motor suitable for general material mixing. Motor and reducer are installed vertically to save space. Air purged shaft seal design. Based on customer’s design and need, this machine can be equipped with either cooling mixing by cold water circulation or hot mixing by kerosene-oil-heated circulation. This type of mixer is also equipped with heat exchanger.

- Tank capacity: 1500L to 10000L.

- Horizontal mixer

- This type of mixer comes with single ribbon mixing blade or double ribbon mixing blade. Double ribbon mixing blade ca blend the material more evenly.

- Feeding capacity: 25L to 7000L.

- Vertical mixer

- Vertical mixer is used for mixing dye, chemical raw materials, and car brake material. It can also diffuse fiber glass, ferrite, cement with sand and dye, and for mixing stabilizer and metallurgic powder.

- This type of mixer is equipped with high speed motor and diffusion tool, which can mix material more evenly in a short amount of time, while causing no residual heat and no damage to the quality of mixed material.

- Feeding capacity: 25L to 2800L.

- Round-barrel mixer

- Round-barrel mixer is suitable for many kinds of material. It is equipped with high speed motor and diffusion tool, which can mix material more evenly in a short amount of time. No residual heat and no damage to the quality of mixed material.

- This type of mixer is used for mixing car-brake material, diffusing fiber glass, ferrite, chemical raw materials and textile fiber.

- Special designed mixer

- Our engineering team can work with customers to specifically design any type of mixer that fits their specifications. Please contact us for more details.

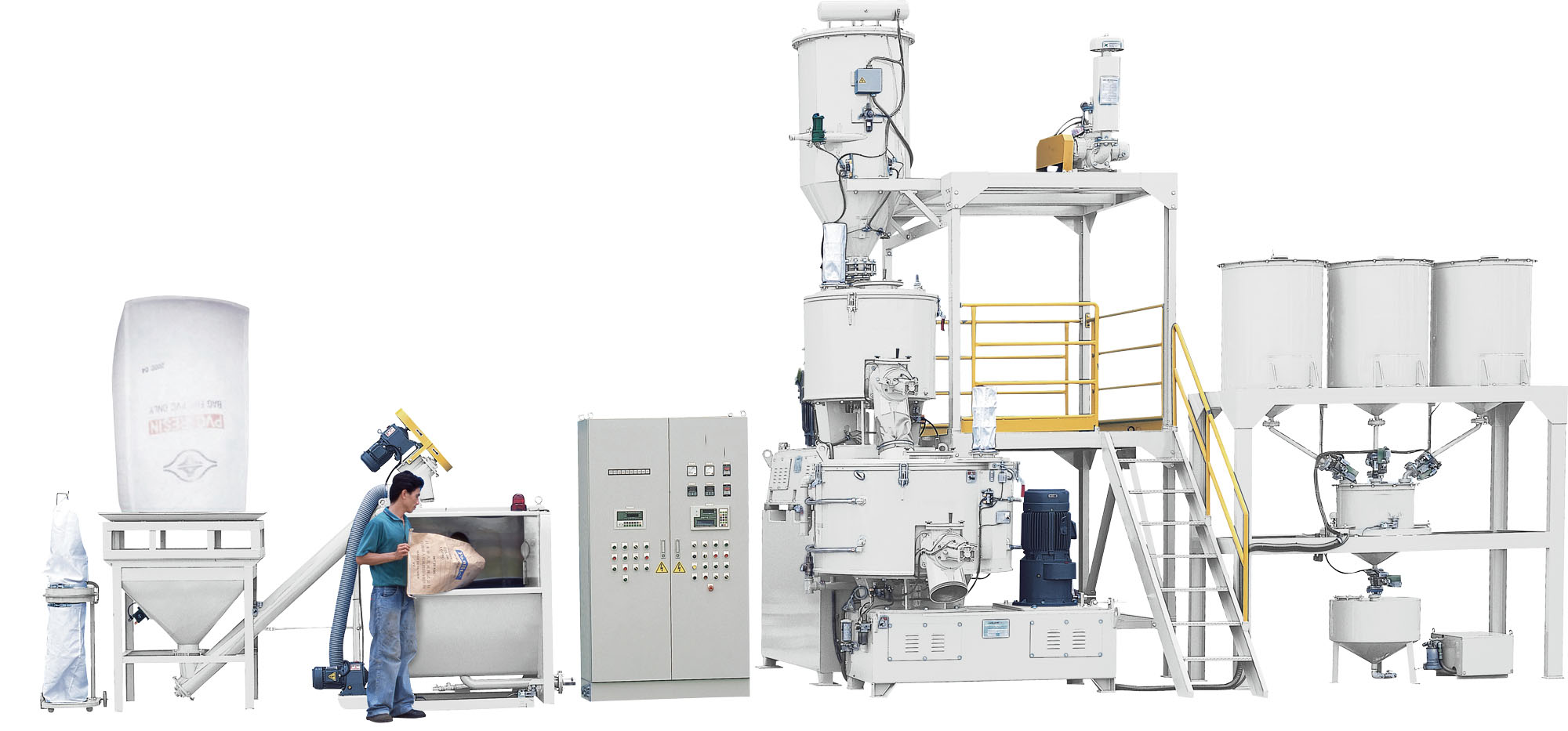

Weighing and conveying system

- Our PVC automatic metering and conveying system has storing barrel for vacuum packages and storage function, it also automatically handles powder package conveying, featuring easy operation, and avoiding the need to carry and add raw material at mixer operation platform. It also prevents dust leakage which saves labor and time, and helps reduce processing cost. This is an environmental and economical friendly conveyor system that can increase the productivity by 30%. Suitable for the plastic industry.

Pulverizing system

- G type pulverizer

- Suitable materials: HDPE, LDPE, flexible/rigid PVC, polypropylene, polystyrene, polyamide, polyester, copolymers, fluoropolymers, and synthetic rubber.

- Pulverized range: 0.1mm to 2mm quality powder for best flow with a unique designed disc mill.

- GR type rotating pulverizer

- This machine is suitable for pulverizing various materials such as acrylic, PU shoe soles, ABS plastics, wood, grains, minerals, clay, and powder metallurgy.

- GJ type hammering pulverizer

- This machine is suitable for various types of material pulverizing, including false lumps, fiberglass, ceramic figurine, calcium hydroxide, ABS resins, silicon resins, carbon fiber, activated carbon, fine sugar, soybean powder, rice and grain hulls, and calcined oyster shell.